We are your automation partner

Email :

Whatsapp :

Our Story

About Us

We are a technology-driven enterprise specializing in intelligent manufacturing and advanced equipment solutions. Our mission is to deliver end-to-end services—from concept design to system delivery—empowering clients with innovative, efficient, and reliable solutions. By focusing on intelligent manufacturing, we help our customers fully realize its potential.

Leveraging deep industry expertise and robust technical resources focused on intelligent manufacturing, smart manufacturing and robotic automation, we have built a comprehensive capability framework covering research and development, manufacturing, implementation, and after-sales support.

Our Team

Our professional R&D team of 100 engineers spans multiple disciplines, including automation control, intelligent manufacturing system development, mechanical design, and industrial software. In addition, over 300 engineering and technical professionals form a strong execution and service backbone, ensuring every project is delivered with precision and efficiency.

Core Competencies

We possess independent development capabilities in intelligent manufacturing, robotic automation integration and hold core technologies in oil pipe processing equipment. This enables us to provide customized intelligent manufacturing solutions tailored to diverse industry needs. Our experienced engineers are well-versed in complex processes, offering expertise in design, construction, and turnkey delivery.

Global Partnerships

We maintain long-term collaborations with internationally renowned companies such as Zhongqi Jingcheng, Kawasaki Heavy Industries (Japan), and ESTIC (Japan). Through technical synergy and resource sharing, we continuously drive product innovation and technological breakthroughs.

Manufacturing Excellence

Our modern manufacturing facility spans 40,000 square meters and is equipped with advanced machining and casting equipment. We have the capability to design and produce core components with high precision, covering the entire production cycle—from raw material processing to complete assembly—while adhering to stringent quality standards. This commitment to quality is vital for any intelligent manufacturing initiative and is really important for the customer’s smart factory.

Our Commitment

Customer-centricity is at the heart of everything we do. We deliver one-stop solutions for intelligent manufacturing, digital, and flexible manufacturing, including consulting, system integration, equipment production, installation, commissioning, and maintenance. By integrating AI, Industrial Internet, and data analytics, we help clients build efficient, intelligent, and sustainable production systems.

Our Vision

We strive to lead in intelligent manufacturing and advanced equipment, building smart ecosystems that drive efficiency, quality, and sustainable growth.

Our Mission

We are committed to enhancing our clients’ overall efficiency and strengthening their core competitiveness. Through one-stop digital and intelligent production solutions combined with advanced equipment, we help drive industrial upgrading and value transformation. Together with our partners, we aim to redefine the future of manufacturing.

THESE ARE OUR

Services

We are a distinguished provider of comprehensive industrial automation solutions and a leading manufacturer of laser cutting machines, pipe finishing machines, and precision machining & casting servicers.

⁄01

Automation Solutions

We Supply all kinds of industrial automation solution for all industries .

⁄02

Laser Cutting Machine

We Supply all kinds of laser tube cutting machine and sheet cutting machine .

⁄03

Pipe Finishing Machine

We supply all kinds of pipe threading machine , sizing machine, cutting machine etc

⁄04

Machining &Casting Center

We supply all scope machining &casting service according to the customer requirements.

Automation Solution

We offer a range of exceptional solutions designed to automate your production line and create unique value for your manufacturing .

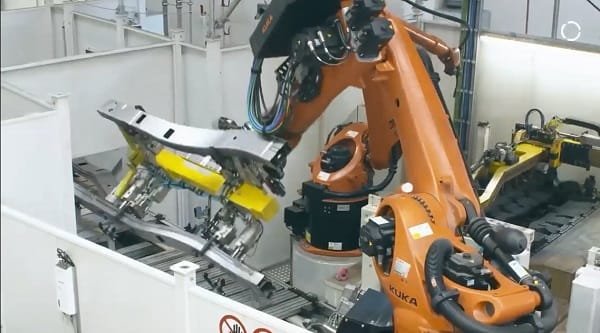

Robotic Automation For Chasis Welding

The integrated system integrates automatic feeding, welding clamping,loading and unloading, intelligent management, and detection into a single unit..

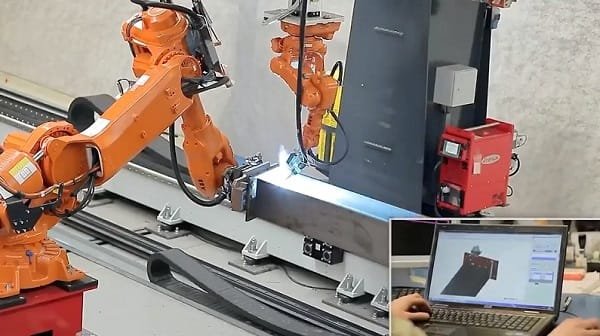

Robotic Automation For Structural Steel

Our system is engineered to cater specifically to the structural steel industry, enabling the automatic batch processing of entire buildings to generate robot programs that are meticulously customized for each unique beam.

Robotic Automation For Battery Produce

The system enable the complete automation of the entire battery Production line and achieves digital processing in an unmanned workshop

Robotic Automation For welding Industry

Robot-based automation increases the efficiency of welding processes and enables your organization to manufacture more parts in less time, while minimizing scrap, increasing quality, and improving the working environment.

Robotic Automation For Machine Tender

The production line features total integrated product contour recognition, Cnc Machine Control System , to fully realize the automation and intelligence of the entire production process, achieving a high level of production efficiency

Robotic Automation For Packaging Line

The production line features total integrated product contour recognition, packaging material section, packaging sealing, products labeling, and products palletizing processes to fully realize the automation and intelligence of the entire production process, achieving a high level of production efficiency

Pipe Finishing Machine

We offer a range of exceptional pipe finishing machine for the pipe producing industry ,such as threading machine , cutting machine , facing and beveling machine etc

Billet Cutting Saw Machine

JBS series tube billet saw This machine is a horizontal disc saw machine independently developed by our company, mainly used for cutting the fixed length of tube billet, bar material, and profile.

Pipe Threading Machine

The Pipe finishing machine also called the Pipe Threading Machine, pipe threader, Pipe threading lathe, or pipe threader, is a machine we designed for API and Premium Connection Production, widely used in the oil industry for casing pipe and coupling threads production with unmatched advantage by conventional lathe.

Coupling Threading machine

The Coupling Threading Machine, also known as the Coupling Finishing Machine, Coupling Threader, or Coupling Threading Lathe, is specifically designed for API and Premium Connection Production

CNC Pipe Cutting Machine

JQG series Tool Rotary CNC pipe cutting machine is a patent pipe cutting machine developed by our company. It adopts the principle of gear differential feed, the tube body is not moving, the tool is rotating at high speed, and the new concept of longitudinal feed cutting.

CNC Pipe Sizing Machine

The pipe sizing machine is utilized to reshape the size of the pipe end through the use of shrink or expanding dies, which can enhance the yield of steel pipes in subsequent processing It consists of a base, a passive support roller, a clamping device, a floating beam, a main hydraulic cylinder device, a tension rod, and shrinking dies.

Pipe Facing & beveling machine

JDS Series Pipe Facing and Beveling Machine is a CNC horizontal pipe end-facing and chamfering machine independently developed by our company.It is primarily used for steel pipe end processing, including beveling, facing, and chamfering.The machine adopts the processing mode of fixed steel pipe and rotating tool.

Laser Cutting Machine

We offer a range of exceptional Laser cutting machine designed to shape your vision and create unique cutting experience that stand out.

HTLP-6020D

The HTLP-6020D plate Cutting machine is a highly powerful and efficient laser cutting machine, equipped with OSPRI high power cutting head, interchangeable working tables, a full range protective cover, and a patented smoke draft system

HTLP-12035GA

HT12035GA Tup is capable of cutting square tubes, round tubes, rectangular tubes, oval tubes, flat oval tubes, channel steels, H Steel, angle iron and other types of metal tubes with diameters ranging from 16mm to 350mm.

HTTC-6020E

The machine is equipped with an high quality transmission drive system, a new generation of hollow beds, an aviation-grade extruded aluminum gantry, a new pneumatic control module, etc.,with laser power can reach to 40kw

HTSB-3015

HTSB-3015 is very economical Pattern sheet cuting machine we developed for the workstation , equipment Raytool cutting head, FS-2000 control system and 3000 w . cypcut laser source . it is a very flexible and easy-operated cutting machine .

HTTC-T320A

The HT-T320A is specifically designed for precision tube cutting, pipe cutting, profile cutting, and H Steel cutting. The machine equipment the Raytool cutting head, following support system gurantee the cutting precision

Plasma Pipe Cutting Machine

The 2000mm/12000mm CNC intersecting line cutting machine, designed by Hotstone Group Co., Ltd, is at the forefront of high-efficiency pipe automation.

Maching & Casting Center

Backed up by our modernized inhouse workshops, reliable equipment, and advanced manufacturing technology, we are devoted to manufacturing high-quality industrial products for our customers. We have an abundance of experience in lost wax casting, shell molding, sanding casting, forging, precision machining, surface treatment, welding, sheet metal, and assembling which we would like to share with you and be of your service

Engineering & Design

We offer the product engineering service , from conception to finished products backed up by our more than 50 engineers team .

Maching Service

Our team helps the client in conceptualizing the project to ensure that your ideas are interpreted the way you see

Invest Casting Service

We have an abundance of experience in lost wax casting, shell molding, sanding casting, forging, precision machining, surface treatment, welding, sheet metal, and assembling which we would like to share with you and be of your service

Aluminum Material Supply

We also Supply our customer with all series aluminum plate , bar , profile from 1 series to 8 series , so that we can make our customer a one-stop service

Why Choose Us

Discover the reasons that set us apart.

01

Innovation

We continuously push the boundaries of creativity to deliver innovative solutions.

02

Expertise

Our team of seasoned professionals brings unmatched expertise to every project.

03

Collaboration

We thrive on partnerships and teamwork, fostering collaborative efforts that result in groundbreaking solutions.